- HOME›

- Product details›

- Hydroforming Press

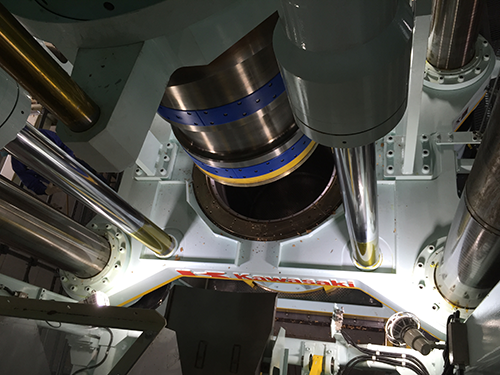

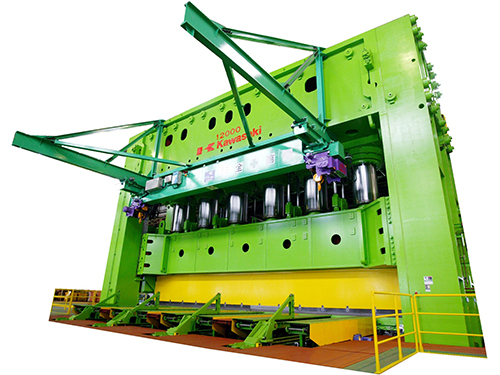

Hydroforming Press

| Kawasaki Hydromechanics Corp. worked on production of the hydroforming press for automobile parts and the development of the basic forming technology since 1998. We also have experience in producing hydroforming products, and we can propose various functions and necessary peripheral device for forming. |

|

| ■One-shot-forming is possible for complexity shape and different cross section. ■The number of parts and welding process can be decreased by hydroforming. ■Automatic Position detector detects different length of pipes so that additions and corrects edge sealing. ■High-Pressure Double action intensifier is made by KAWASAKI. Limitless output, compact, and energy saving. ■Horizontal cylinder adopts Hybrid Servo control unit. High accuracy and various free motions ■Forming data setting is easy by Step-Chain control and Date-Logging made with KAWASAKI. ■Pre-Filling circuit and Filling circuit contributes the short forming cycle time. |

|

| ■Material feeder /work unloader ■Various die changer ■Auto coupler ■Hydraulic / air circuit for die ■Forming axis addition ■Pre-forming Press ■Pipe bending device and Edge cutting device |