- HOME›

- Technology

Technology Development

- Design based on analysis

- Truck chassis forming press

- 4-point high precision levelling device

- Hybrid press

- In-plant design & fabrication

- Wood chip dehydrator

-

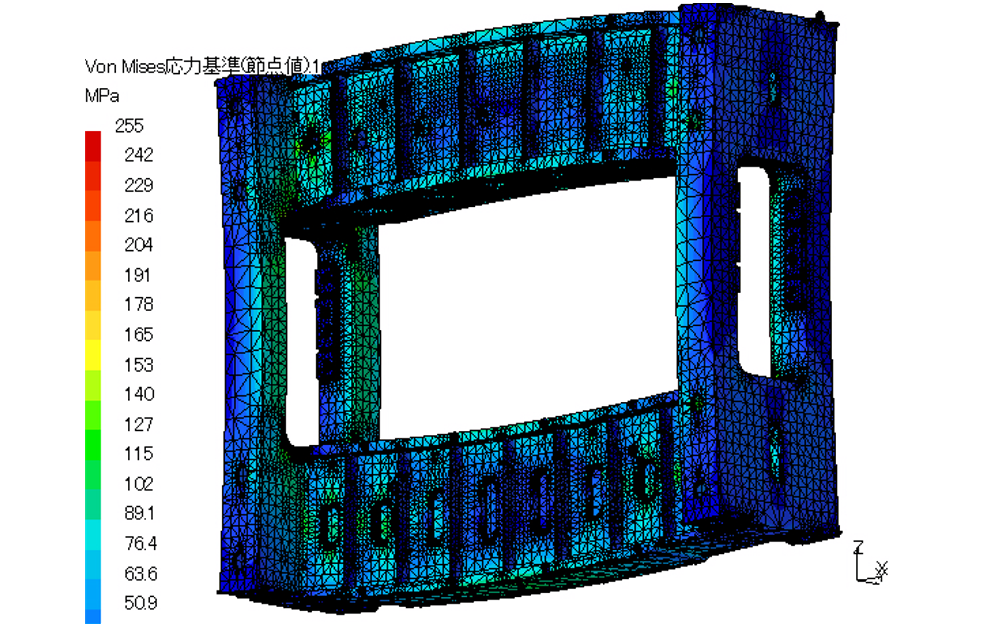

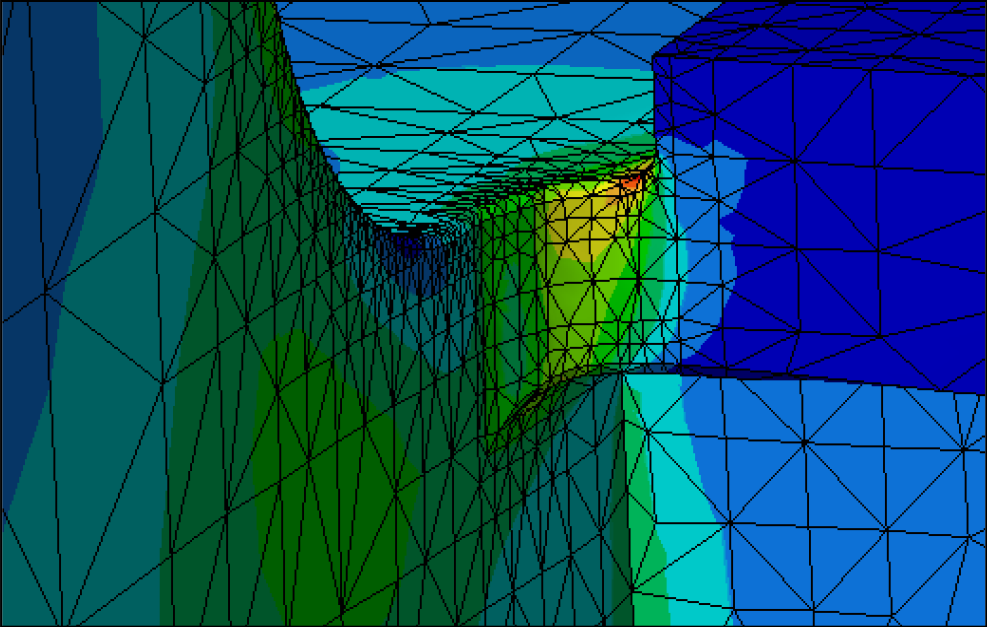

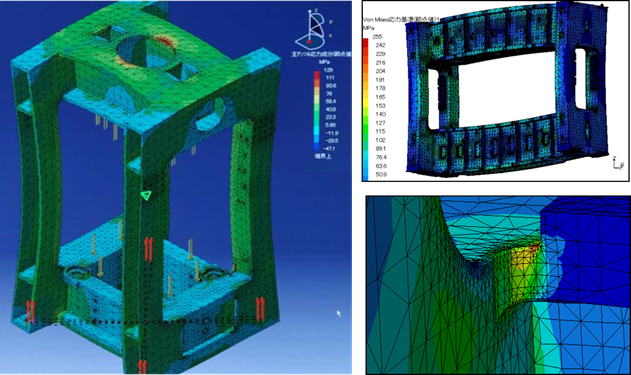

Design based on analysis

Design based on analysisIn conventional structural analysis (two-dimensional frame calculation),

the design is performed at the representative cross section to be analyzed,

but FEM analysis makes it to be possible to model the frame structure and

to be able to point out the stress conditions to inform it to designer.

-

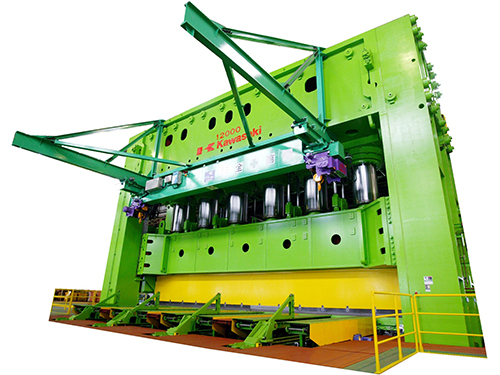

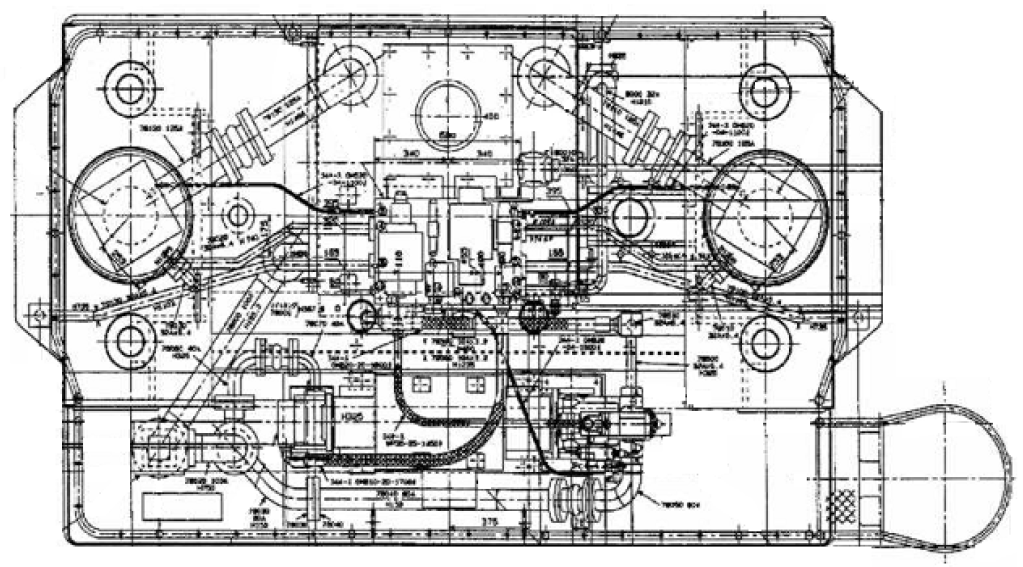

Truck chassis forming press

Truck chassis forming press

■Main specification

Output 50000kN Dimension of bolster 12280 × 1600㎜ Daylight 1700㎜ Stroke 850㎜ Descending speed 270㎜/s Pressing speed 19~9.5㎜/s Ascending speed 230㎜/s Cushion 750kN×8 Moving bolster Left・Right moving×2 Balancer 20000kN(5000×4) Slide KO 100kN×20 Main Motor 110kw×6 Cushion motor 15kw×8(servo motor) Control imagination

■Features

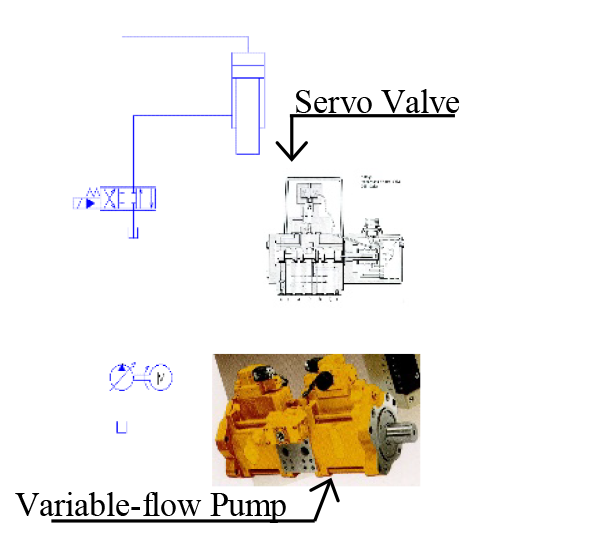

■Servo valve control realizes the precision ±0.05mm of slide stop position.

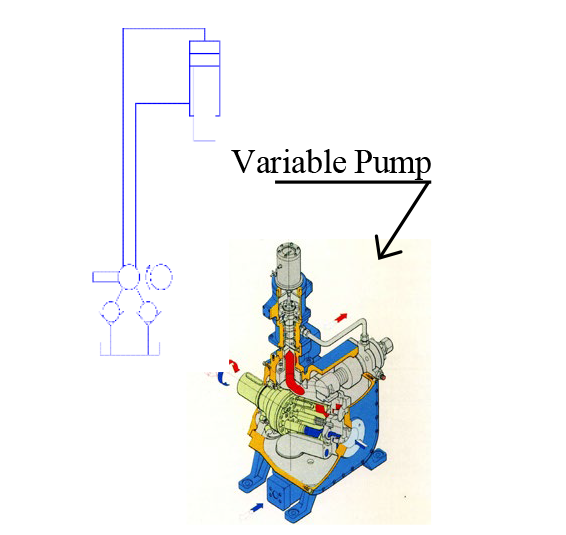

■Power saving compared to past press by adopting variable pump.

■Cushion is controlled seperately.

■Slide 2 ponit pallarel control is adoppted for long size eccentric forming.

■The total solution of press machine and automation is our proposal.

-

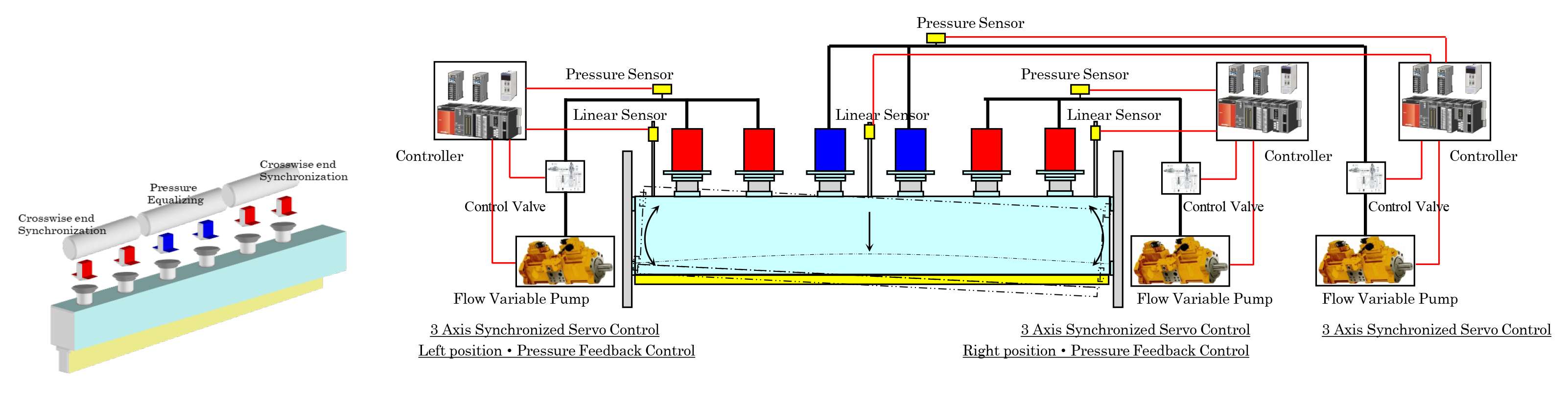

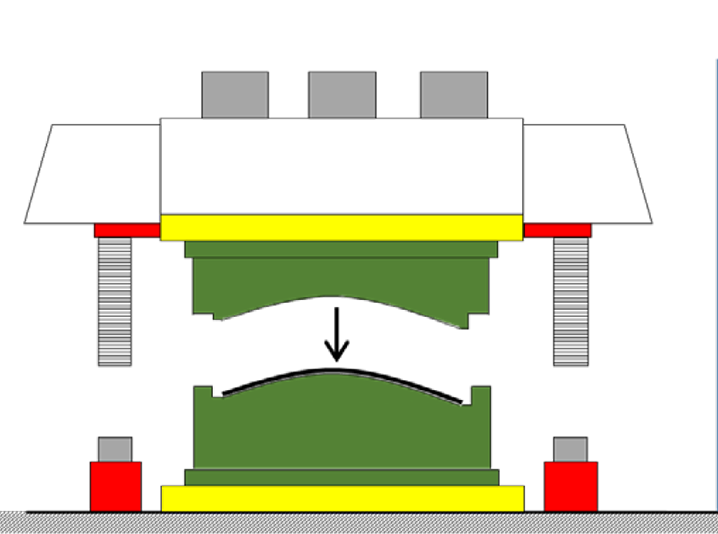

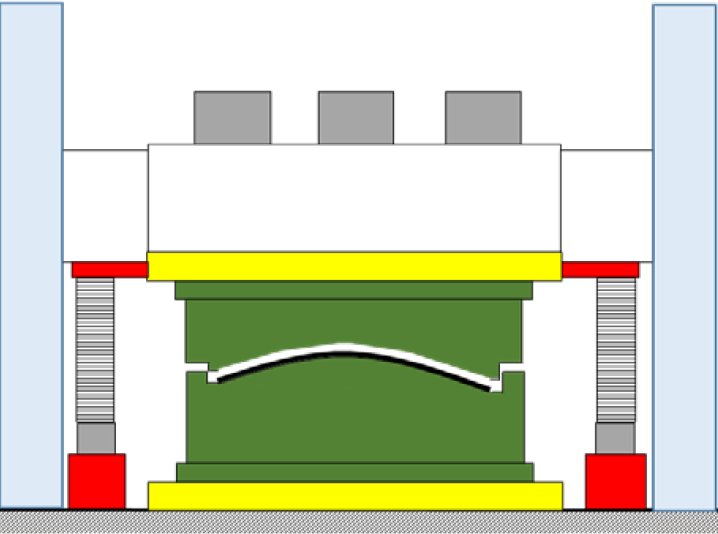

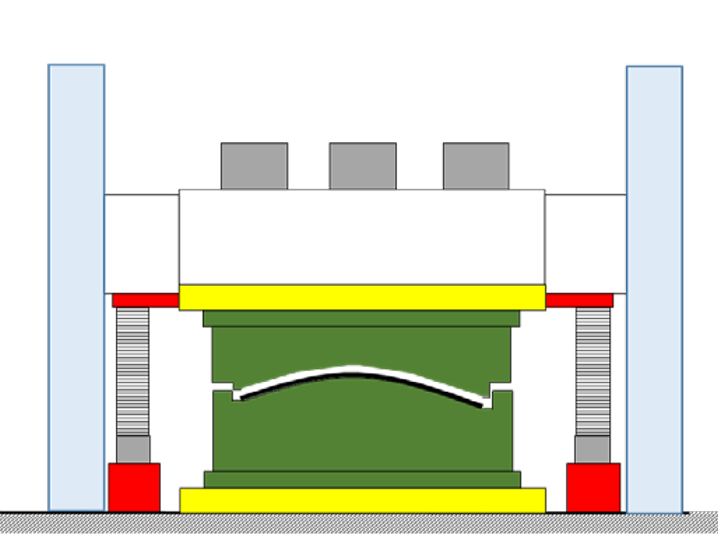

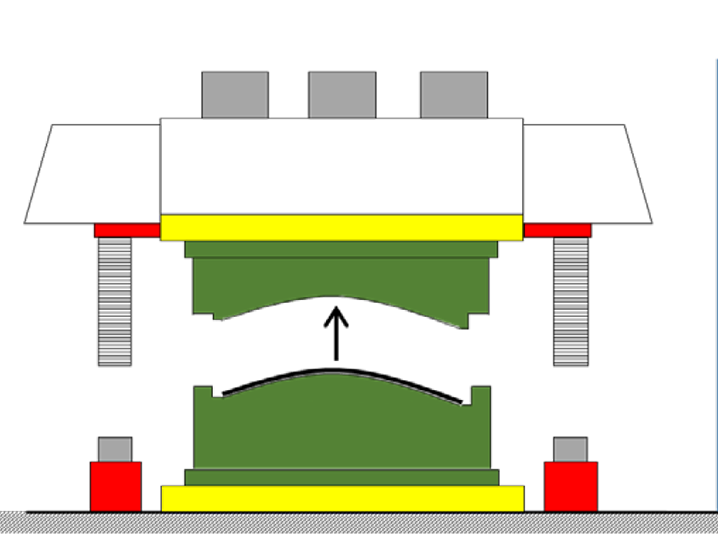

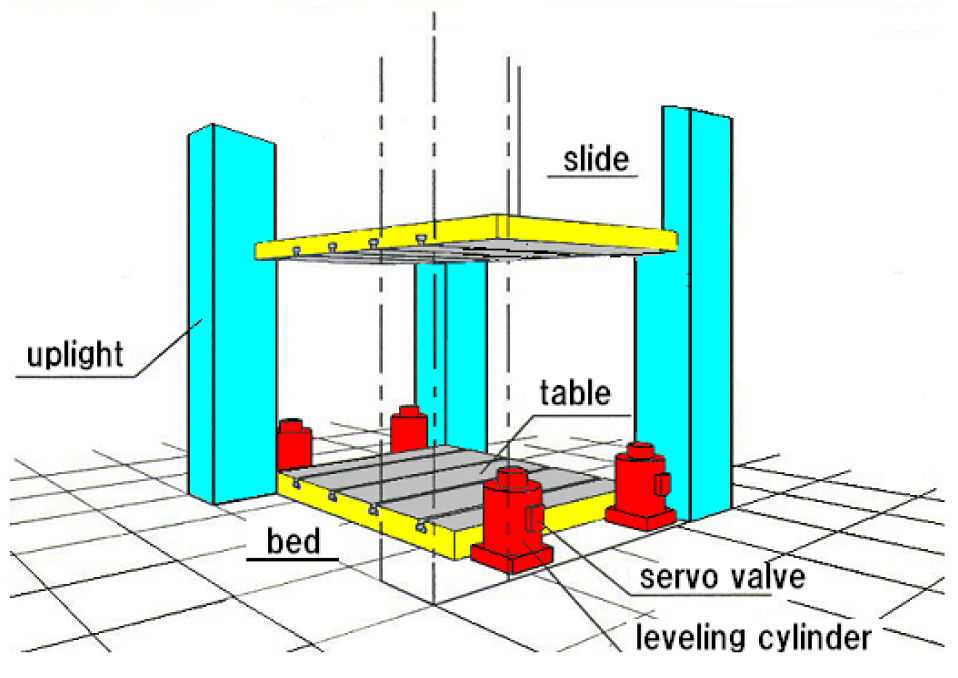

4-point high precision levelling device

4-point high precision levelling device-

Descending

-

Levelling Touch

-

Pressing

precision ±0.05mm

-

Mold Open

&

Ascending

precision ±0.05mm

-

Slide 4 point paralel control during pressing/mold open/slide ascending

stop accuracy ±0.05mm

dynamic accuracy ±0.1mm

standard speed 0.1mm/sec or slower -

-

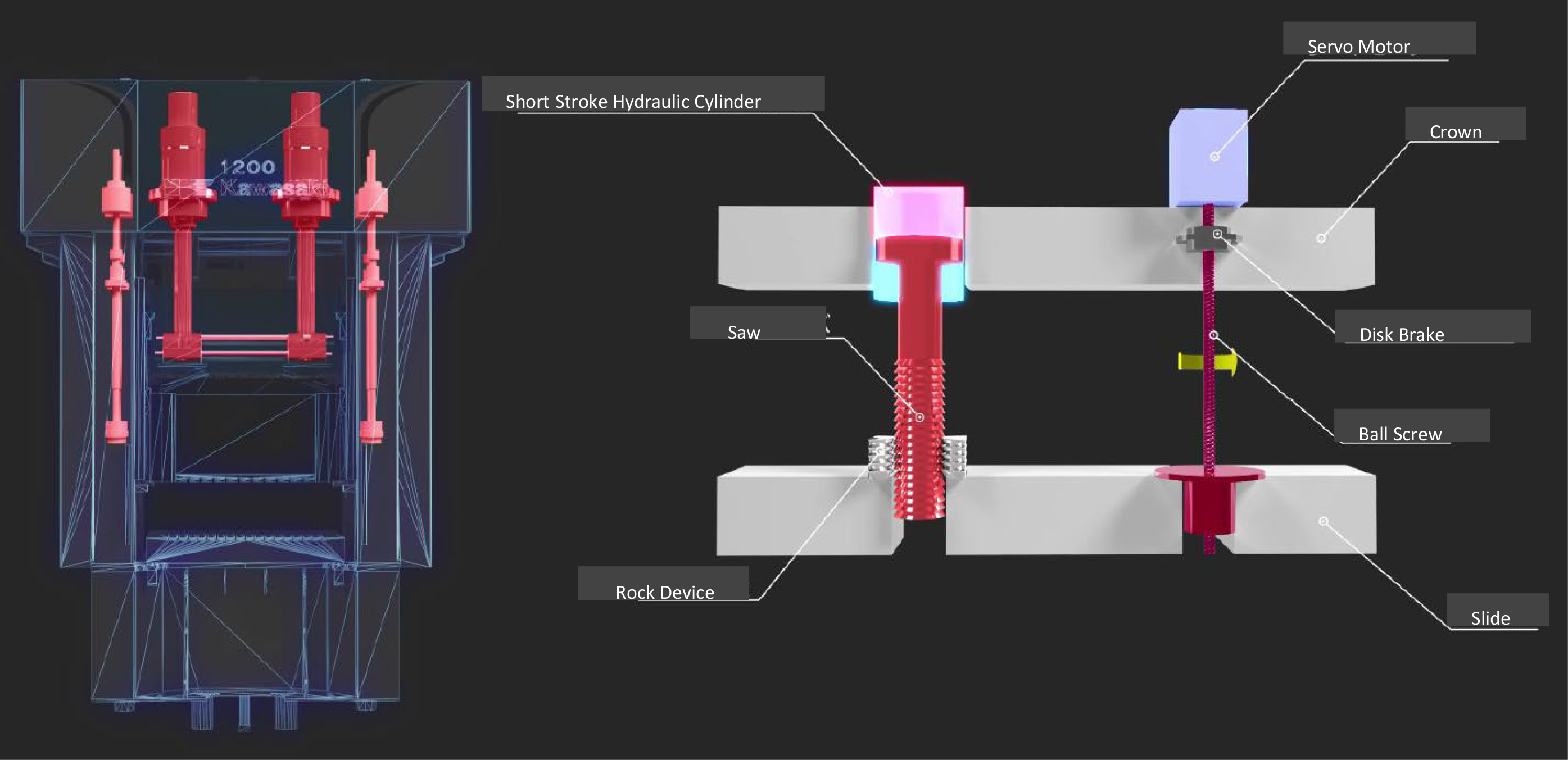

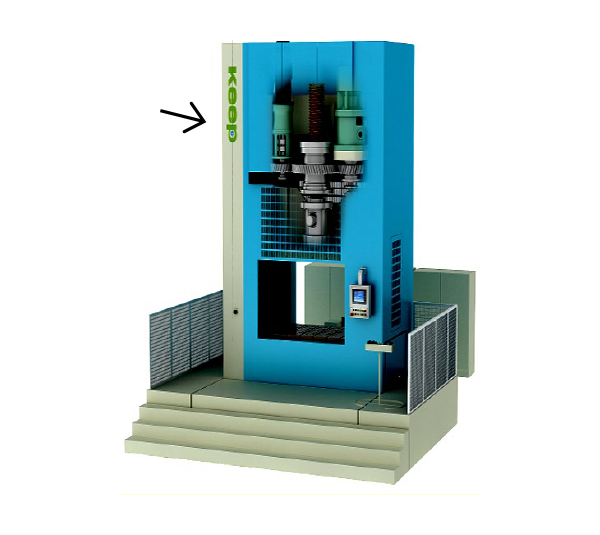

Hybrid press

Hybrid pressNew developed hybrid press with integration of hi-speed electric servo drive and hi-precision hydraulic drive .

■Main specification

Main press / hydraulic drive Pressing capacity 12000kN Daylight 2500㎜ Max.stroke 1900㎜ Table size 3000×2000㎜ Pressing speed 60~9.5㎜/s Main press / screw drive Pressing capacity 1000kN Descending speed 550㎜/s Ascending speed 550㎜/s Die cushion Cushion capacity 3000kN Max.stroke 400㎜ 4-point leveling position adjuster Leveling capacity 1000kN×4 Max.stroke 99.99㎜ Descending speed 10~0.1㎜/s Ascending speed 10~0.1㎜/s Detaching capacity 2000kN -

-

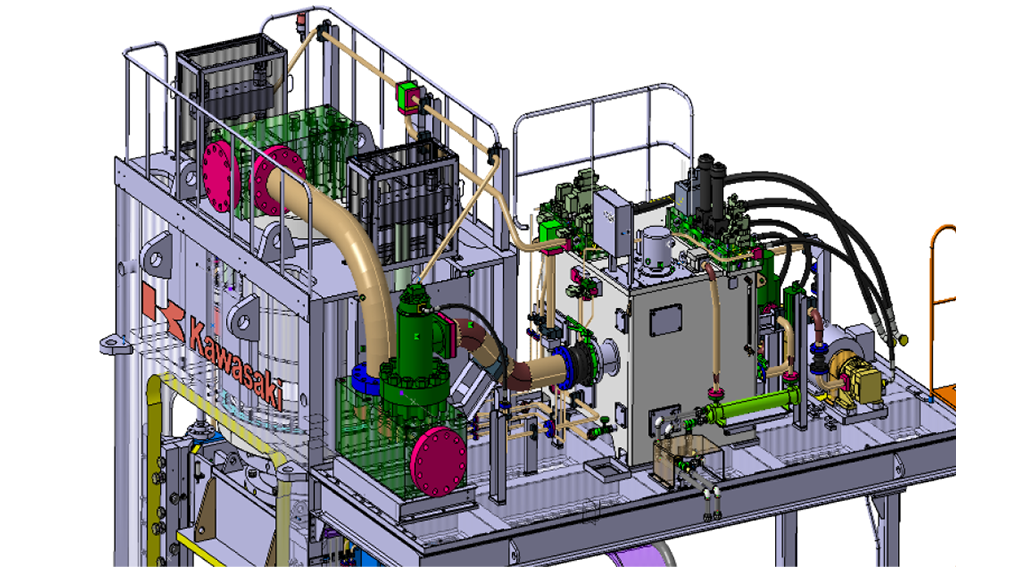

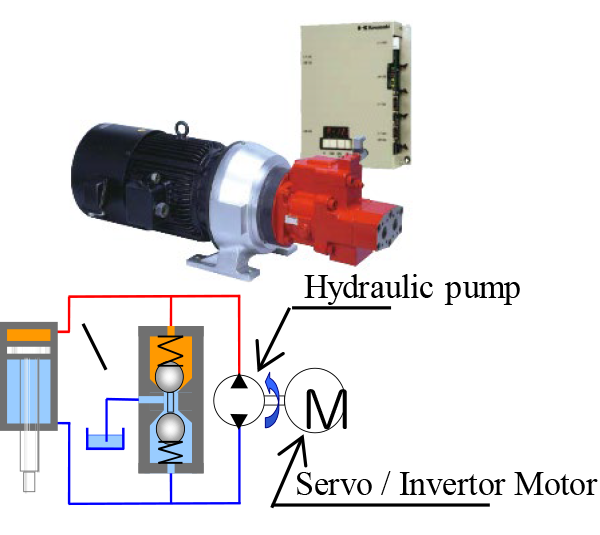

In-plant design & fabrication

In-plant design & fabrication■Design

Rationalization design based on press frame F.E.M Analysis

each oil pipe matches its original fabrication drawing.

Pipe drawing makes it possible for quick change and on piping work out of manufacturer.

Also, piping routine is designed with 3D-CAD, it is possible for the convenience of maintenance.Kawasaki original hydraulic control based on abandant know-how on over 2000 presses.

-

D-SERVO/ Electric

-

K-SERVO / Oil Hydraulic

-

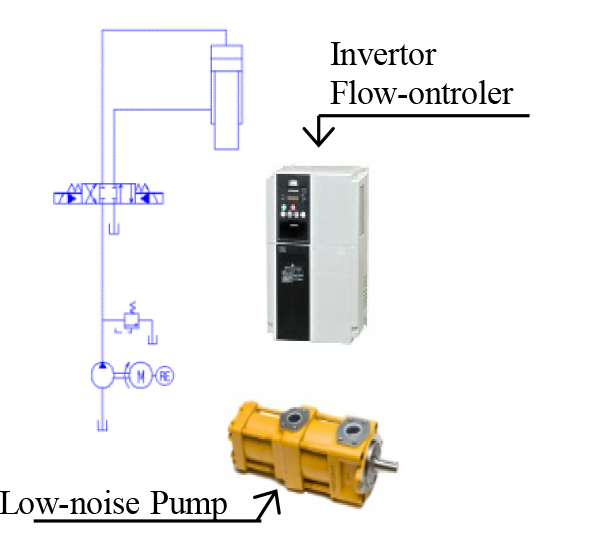

Invertor / Oil Hydraulic

-

Servo Valve / Oil Hydraulic

-

Pump-P / Oil Hydraulic

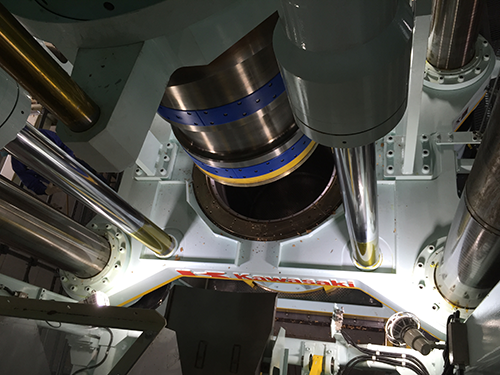

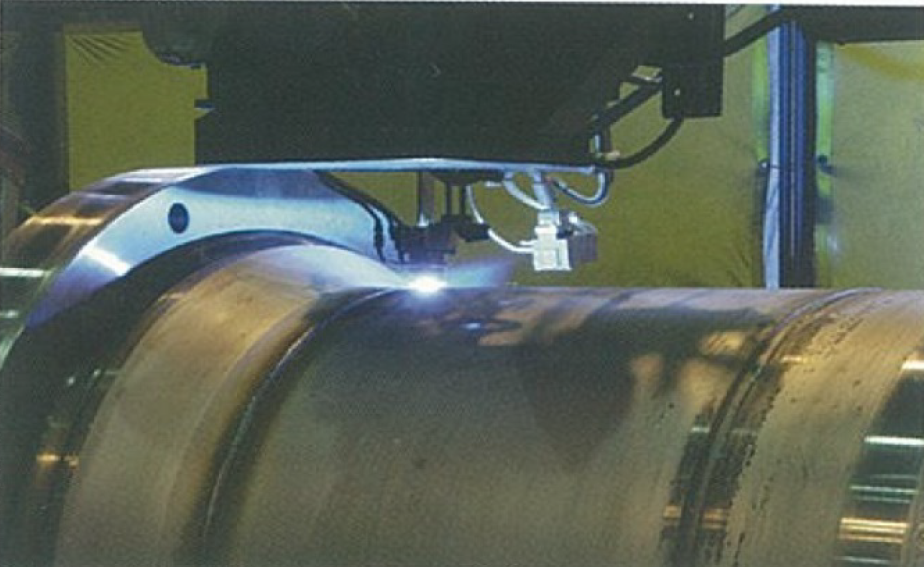

■Fabrication

Strict quality and delivery management

Steel blanking, welding, maching and assembly are performed in one plant to improve the realiability of our press machine.-

Large size machinery -

Automatic Welding

-

-

Wood chip dehydrator

Wood chip dehydratorDedicated machine of “squeezes water from trees” (patented), equiped with double-action forced drainage mechanism .

■Main specification

Pressing capacity 20000kN Processing Time 130SEC/Cycle Processing capacity 1㎥(300㎏)/Cycle 1Hour Approx. 8 t 1Day(24h) Approx. 200t 1Year(320days) Approx. 64000t Material chip(water contents over 45% ) Water contents after squeezing About40% ■Features

■Double-action forced drainage mechanism (patented) realizes the stable performance of dehydration.

■Wood chips with a water content of 50-70% can be dehydrated to 40% with 130SEC.

■Dehydration is possible with 1/33 power consumption compared to heat drying.

■We supply the total plant solution from chips cutter, convey, dehydration equipment and the feeder.