- HOME›

- Product details›

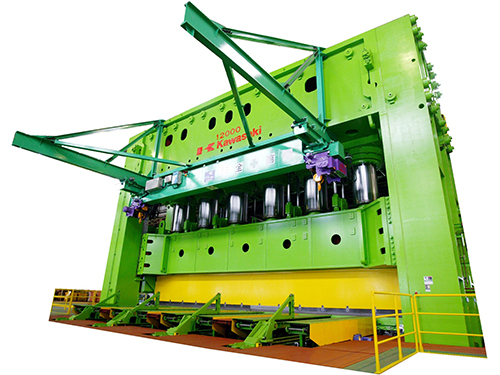

- Chassis Forming Press

Chassis Forming Press

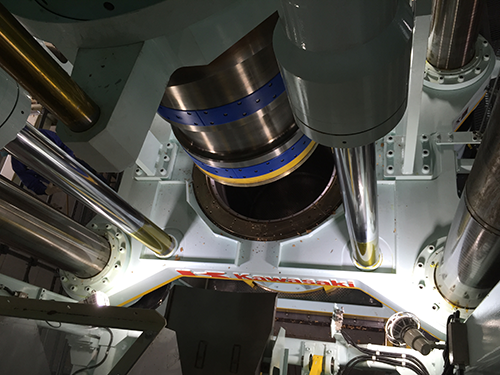

| This is a high-precision chassis press that adopts two-axis slide parallel servo control. Equipped with a balancer device, it can bend and pierce with one press. |

|

| ■ Slide lower limit accuracy of ± 0.05mm is realized by adopting high precision servo valve control method. ■ Adopting a variable pump unit saves energy compared to conventional presses. ■ Equipped with a multi-axis (9axises) high-precision die cushion device, which allows smooth forming at each part of chassis. ■ Position, speed, pressure, time, etc. 100 patterns of forming data can be stored by molding data memory device. ■ Slide parallel control during long size forming is possible by slide 2-axis parallel servo control. ■ Swelling at the center of the product in long molding can be corrected by the slide parallel control. ■ Equipped with a balancer device to buffer breakthrough during piercing. ■ Equipped with left and right bolster moving device, pre-forming die setup is possible. |

|

| ■ Material feeder / unloader device ■ Various die change equipment ■ Hydraulic / air circuit for die |