- HOME›

- Product details›

- Sheet Stretch Former

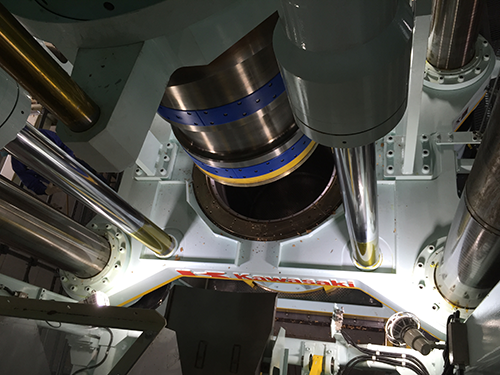

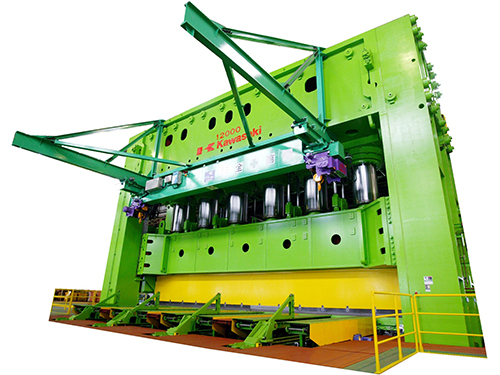

Sheet Stretch Former

| It is a machine for forming metal parts with a three-dimensional compound curved surface such as the fuselage skin of an aircraft. A predetermined curved surface can be obtained by winding the material around the die while applying tensile force. Equipped with a function to add uniform elongation to the entire surface of the material so that it will not be broken due to local elongation of the material. |

|

| ■It is possible by programing in a molding trace of FEM by programing software to reproduce the forming that is close to the result of FEM. ■It is possible to Pre-verification of machine operation by the operation simulation. ■An expected control motion is achieved by mechanical error correction, and automatic forming cycle is realized even for products that require high skill. ■Motion axis consist of all 42 axis that is controlled independently by and separately. ■Achieve the energy saving and high precision for each axis. ■It equipped with various functions. |

|

| ■Die changer ■Moving Floor ■Jaw case unit ■Forming program simulation ■Curved Jaw, Swing Jaw, bulldozer etc. |